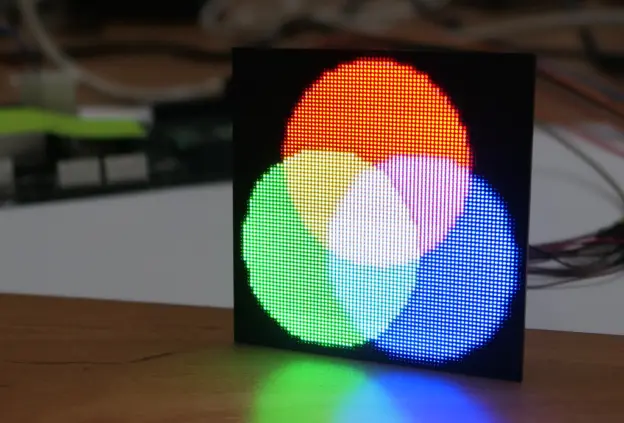

LED (Light Emitting Diode) technology stands at the forefront of modern lighting and display innovations, combining efficiency, sustainability, and versatility. Its unique semiconductor-based light emission offers exceptional energy efficiency, long lifespan, and high reliability. With precise pixel control and color management, LED technology is widely used in high-definition displays, smart lighting, and creative lighting solutions, pushing the boundaries of visual experiences. From small-pitch LEDs to Micro LEDs, each technological advancement paves the way for higher resolution and lower power consumption, opening endless possibilities for industries across the globe.

Excellent chemical and weather resistance, good toughness. PVC is the most widely used plastic, with good mechanical properties, excellent chemical resistance, weather resistance and good toughness. Moreover, PVC material is non-toxic and non-polluting and has a long shelf life

Excellent chemical and weather resistance, good toughness. PVC is the most widely used plastic, with good mechanical properties, excellent chemical resistance, weather resistance and good toughness.

Engineering thermoplastic with excellent mechanical properties and highchemical & abrasion resistance.susceptible to moisture.

High machinability and ductility, good strength to weight ratio. Aluminium has a good strength-to-weight ratio, high thermal conductivity, low density and the ability to corrode naturally.

Excellent strength to weight ratio for aerospace, automotive and medical applications. Titanium is a metal with an excellent strength to weight ratio, low thermal expansion and high corrosion resistance, sterilisation and biocompatibility. .

| Equipment Name | Model | Quantity | Purpose |

|---|---|---|---|

| Mega ball technology | MBT-330MLD | 1 | Automatically send PCB to the machine track for production |

| Hotan Electromechanical | IP42 | 1 | Solder paste automatic printing |

| Samsung | 471 | 6 | Install the resistor, capacitor, diode, triode, IC, LED and other mounting materials on the designated position of the PCB. |

| Samsung | 520 | 9 | Install the resistor, capacitor, diode, triode, IC, LED and other mounting materials on the designated position of the PCB. |

| Samsung | PRO | 2 | Install the resistor, capacitor, diode, triode, IC, LED and other mounting materials on the designated position of the PCB. |

| Samsung | S2 | 3 | Install the resistor, capacitor, diode, triode, IC, LED and other mounting materials on the designated position of the PCB. |

| Samsung | DECAN | 2 | Install the resistor, capacitor, diode, triode, IC, LED and other mounting materials on the designated position of the PCB. |

| Hetong Electromechanical | HF-0802-1F | 3 | Fuse-weld the components mounted on the PCB with the pads on the PCB. |

| Taiyo electronic | POT-203C | 1 | Solder components inserted on PCB. |

| siemens | Aptio | 1 | Transfer the product flow to the next process. |

| Haipai Technology | HP-02624 | 2 | Automatically and evenly spray the protective paint on the designated position of the PCB and automatically dry it. |

| Haipai Technology | PGB-700 | 1line | Automatically fill the required amount of glue. |

| Hongcheng Technology | 001 | 1 | Automatically control the glue cooling time to make the poured glue flow out automatically after drying |

| Kunshan Zhensu Technology | zsc-30 | 1 | Automatically take and place the product in the pool to test the waterproof effect. |

| ESPEC | GF | 1 | Verify the performance and reliability of LED display. |

| Hongruida Technology | 320.V4.0 | 10 |